Broadcast - 22 June 2025

The latest and I must say good news from our training officer Peter VK7PD, another three candidates have qualified for their foundation grade licenses. Congratulations to Rowan VK7III who has received his call sign and to Phil and Denis who are waiting with bated breath to be advised! As soon as I am made aware of the new call signs I will update everyone to listen out for them. Please note that Peter is currently running Saturday upgrade classes, all are welcome, please contact Peter or the secretary if you are interested.

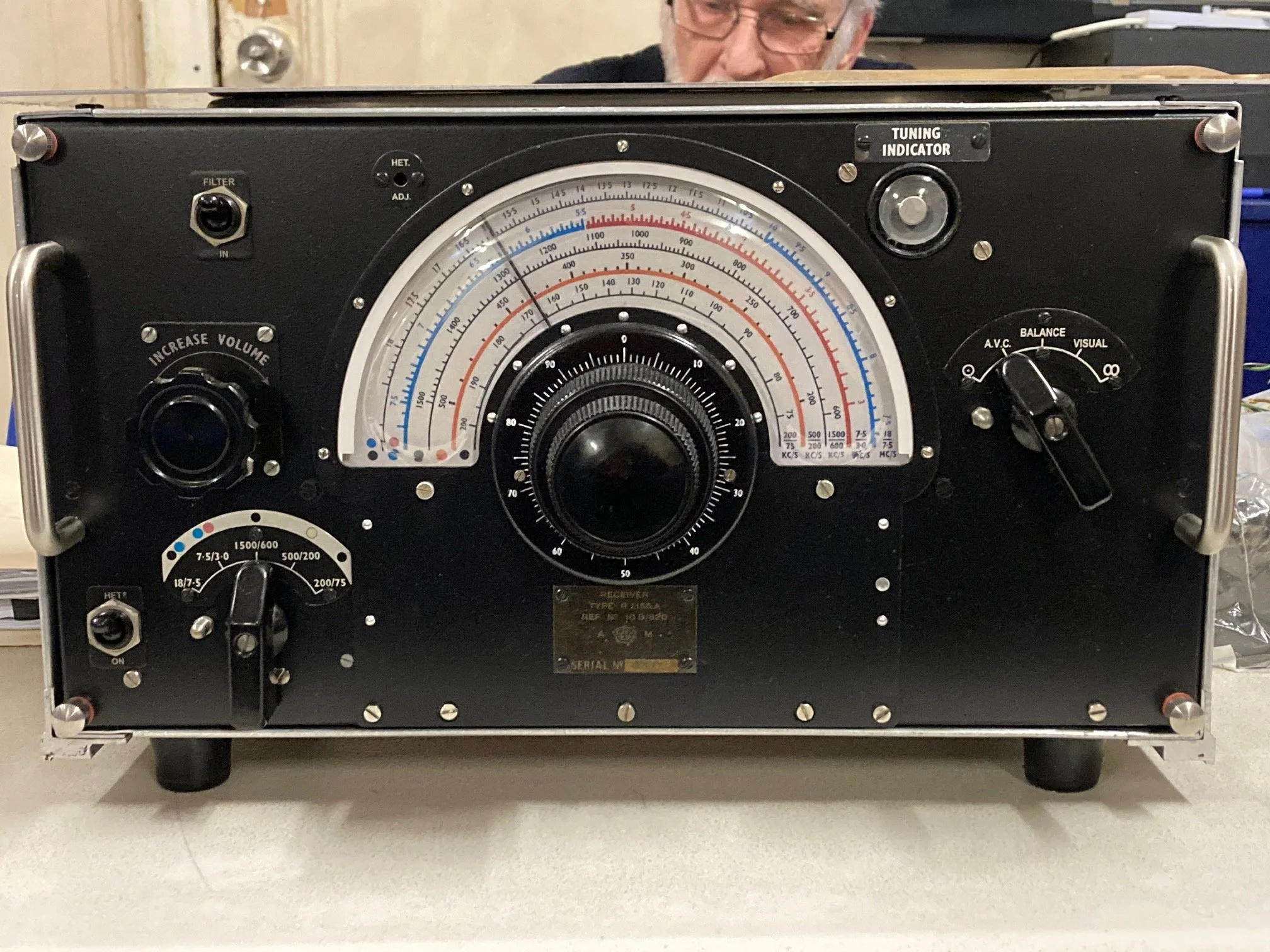

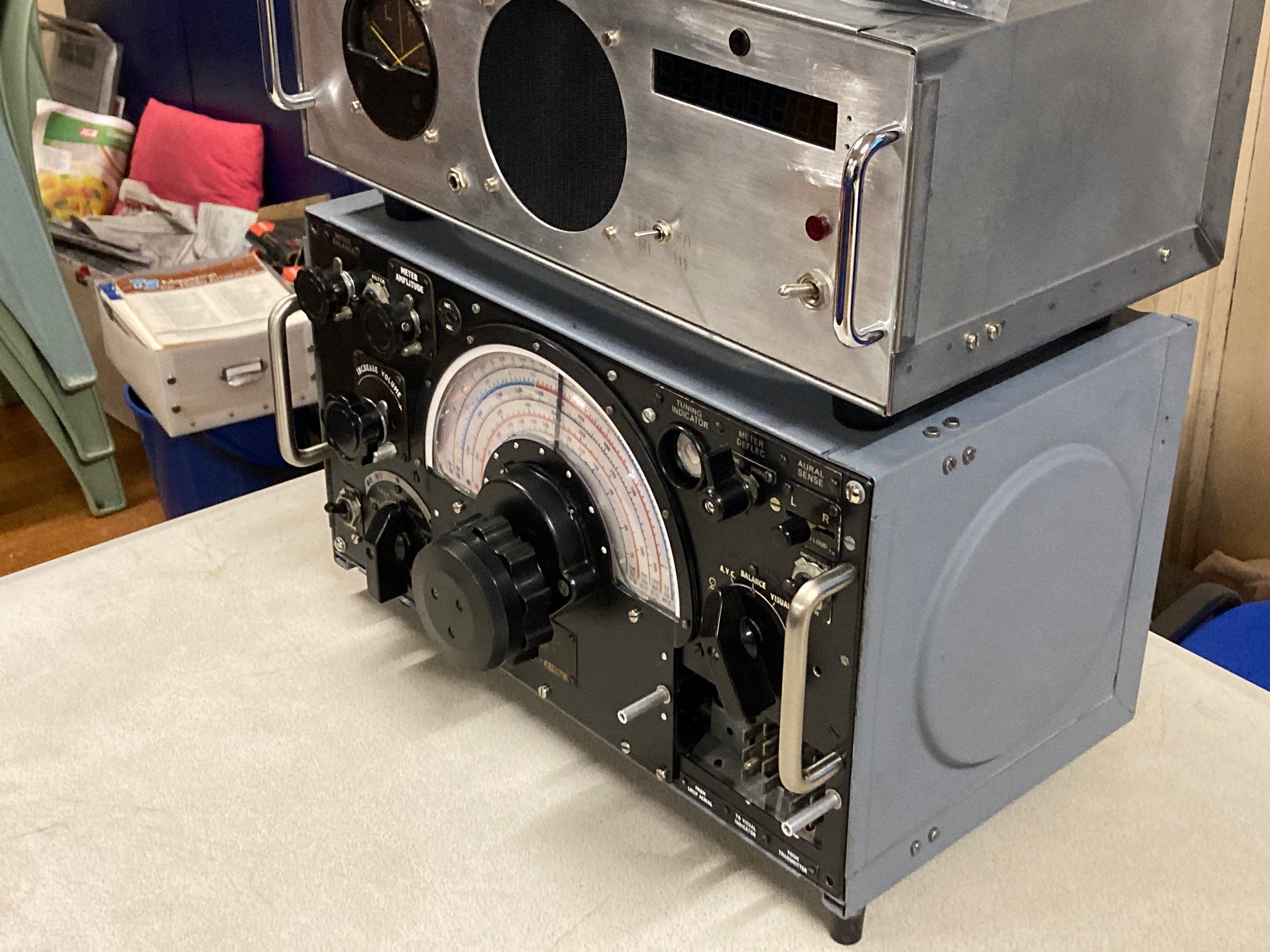

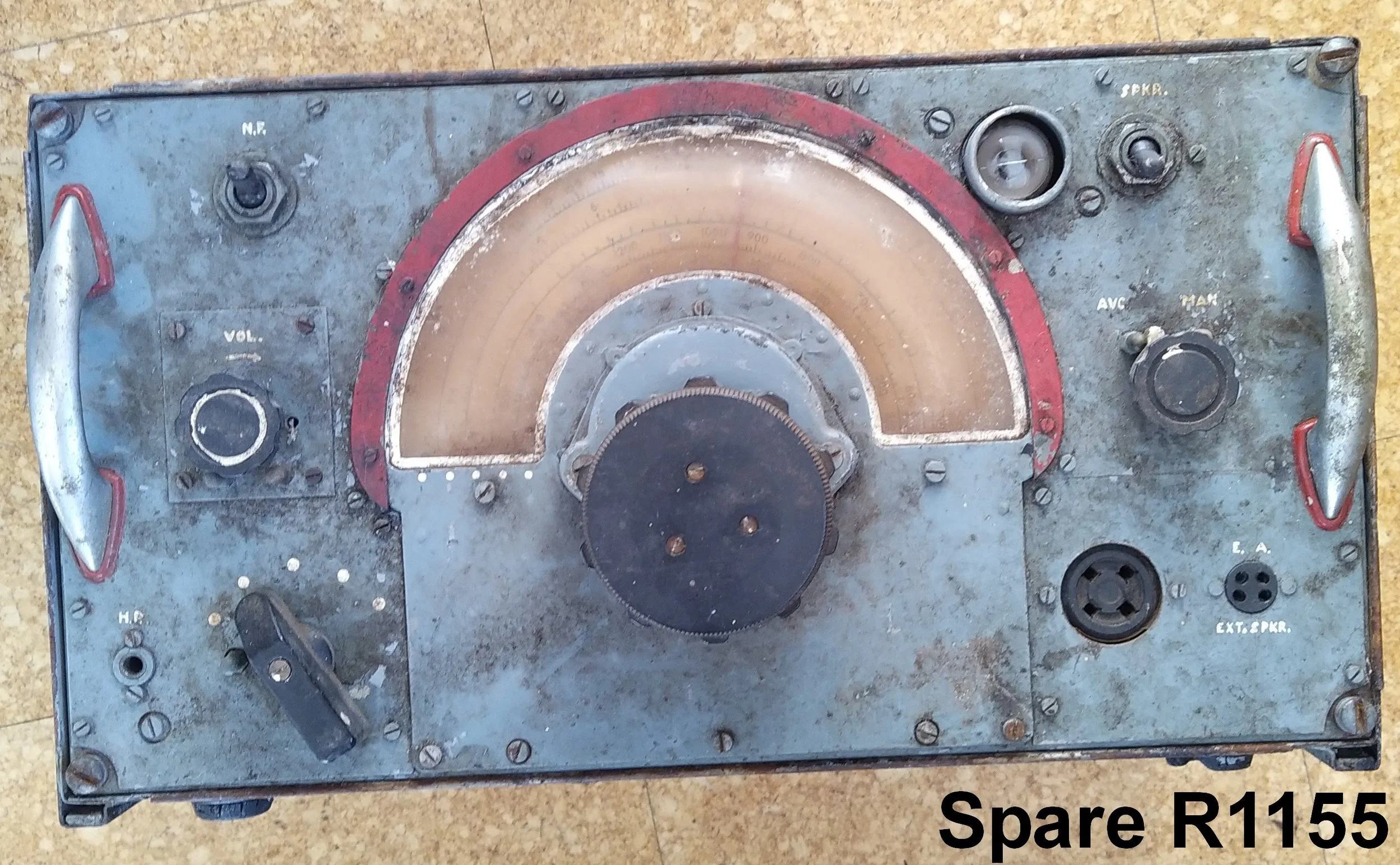

In last week’s broadcast I covered the first part of a presentation by Eric Paul and Trevor VK7TB on the challenges faced when restoring two British Marconi R1155 communications receivers.

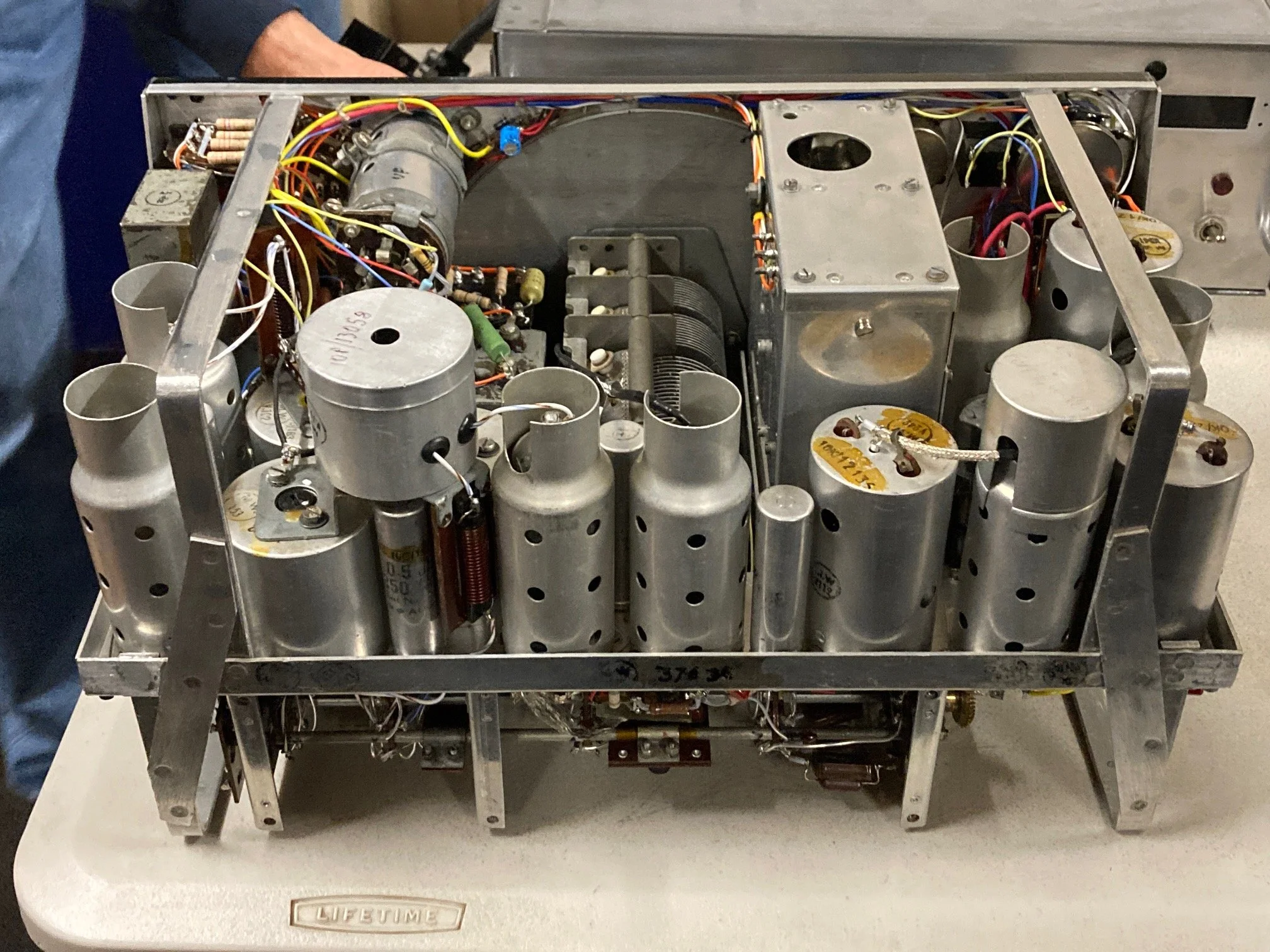

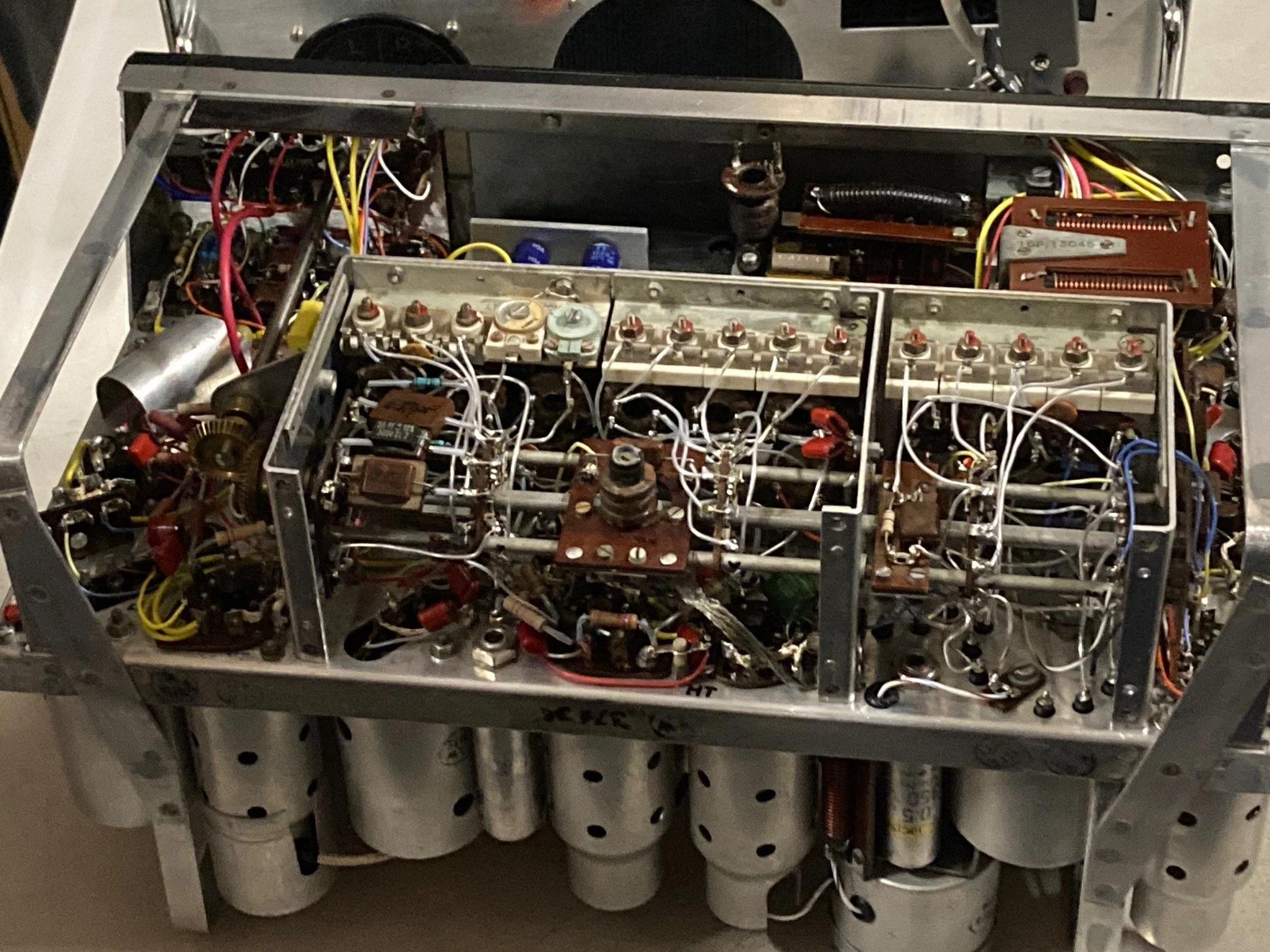

They had acquired three of the Marconi R1115 sets in various stages of decay with none of them even vaguely complete let alone functional. This refurbishment ended up being total strip down, back to empty chassis level with the hope of eventually making two working units. The chassis could be kept but the external cases would have to be remanufactured. One case in steel and the other in aluminium because it was for a Direction Finding version intended for aircraft use. The chassis were cleaned and all additional holes, which were made by enthusiastic amateurs or radio users trying to modify the receivers, had to be filled in and made good.

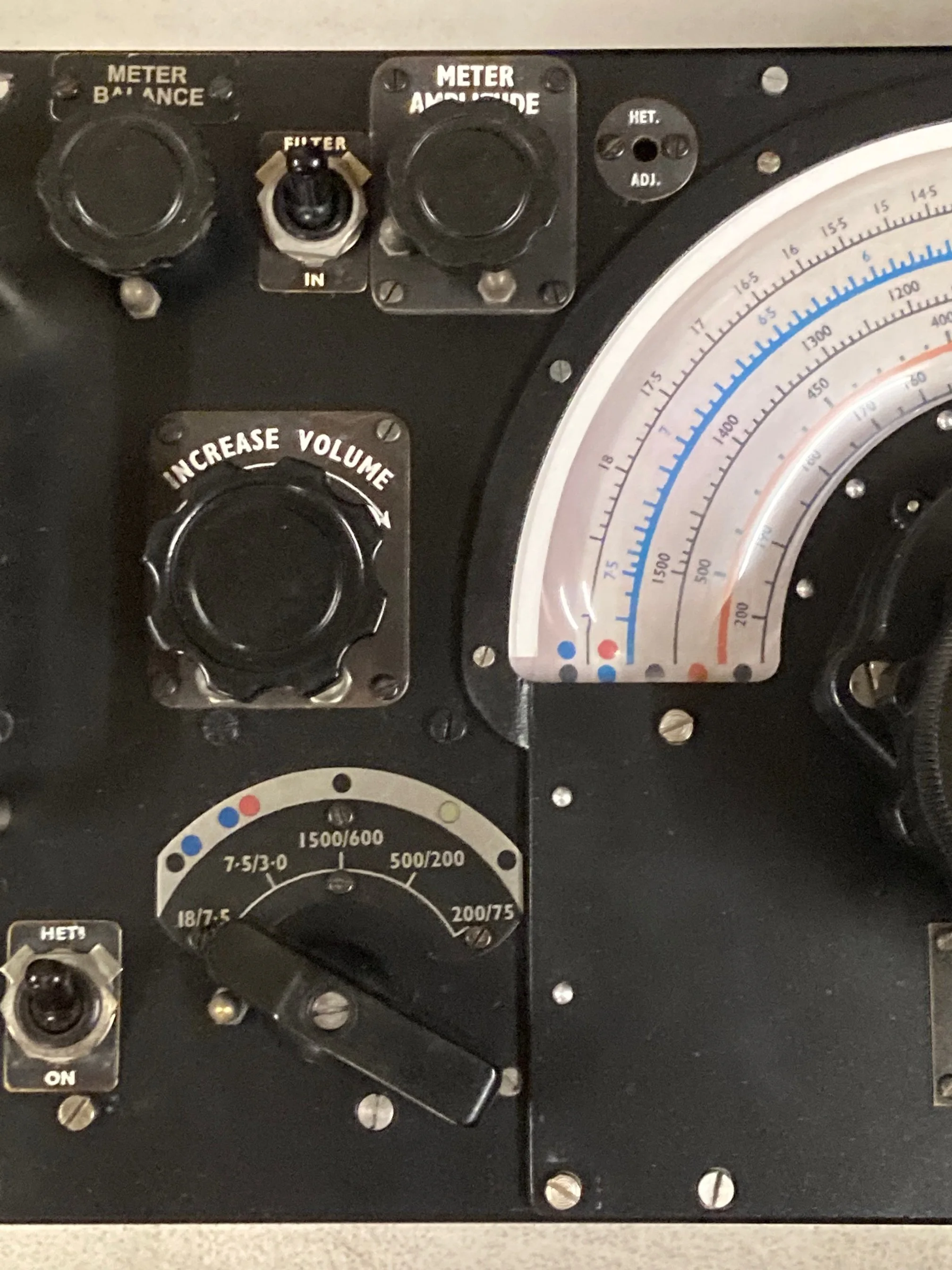

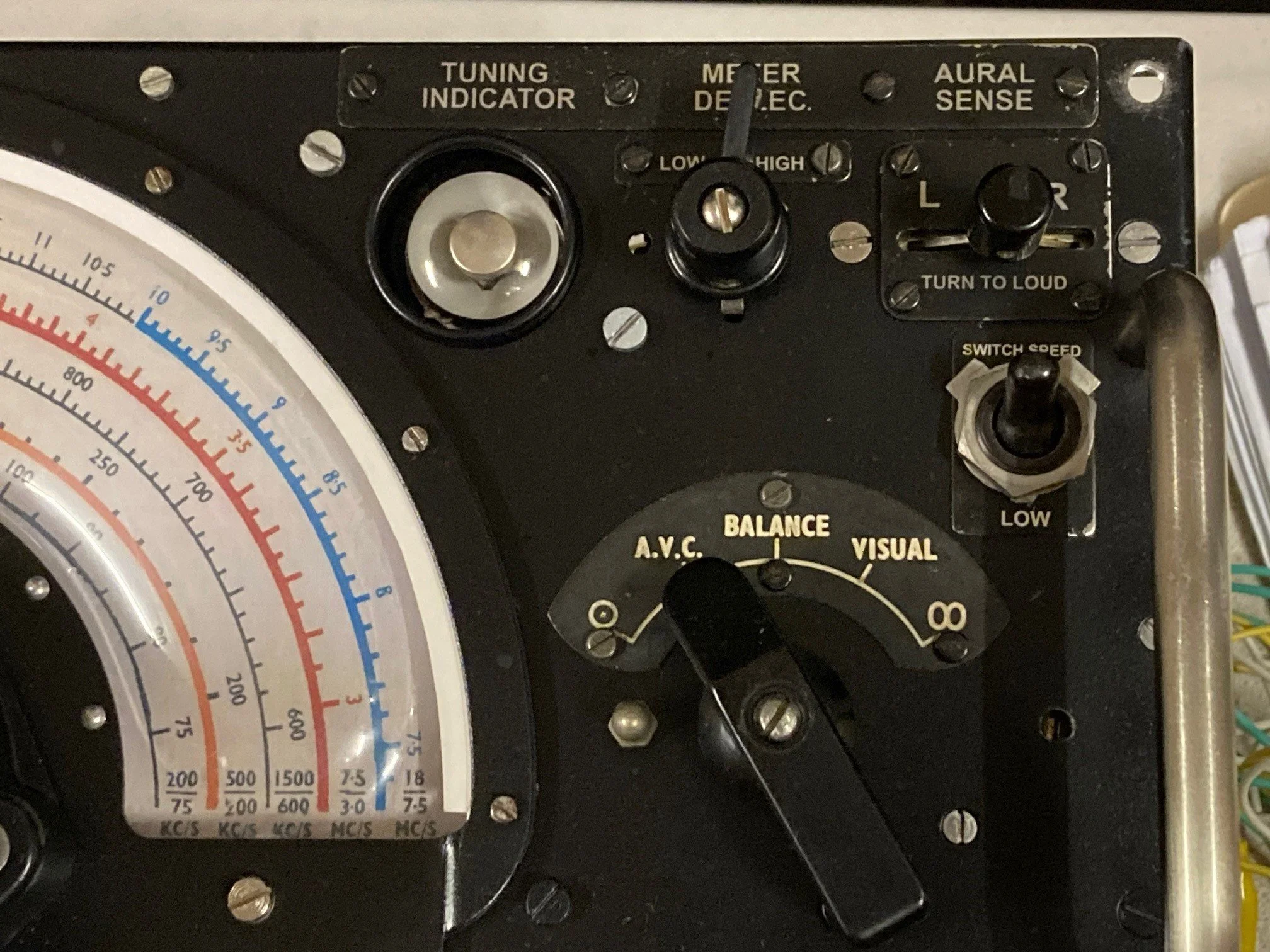

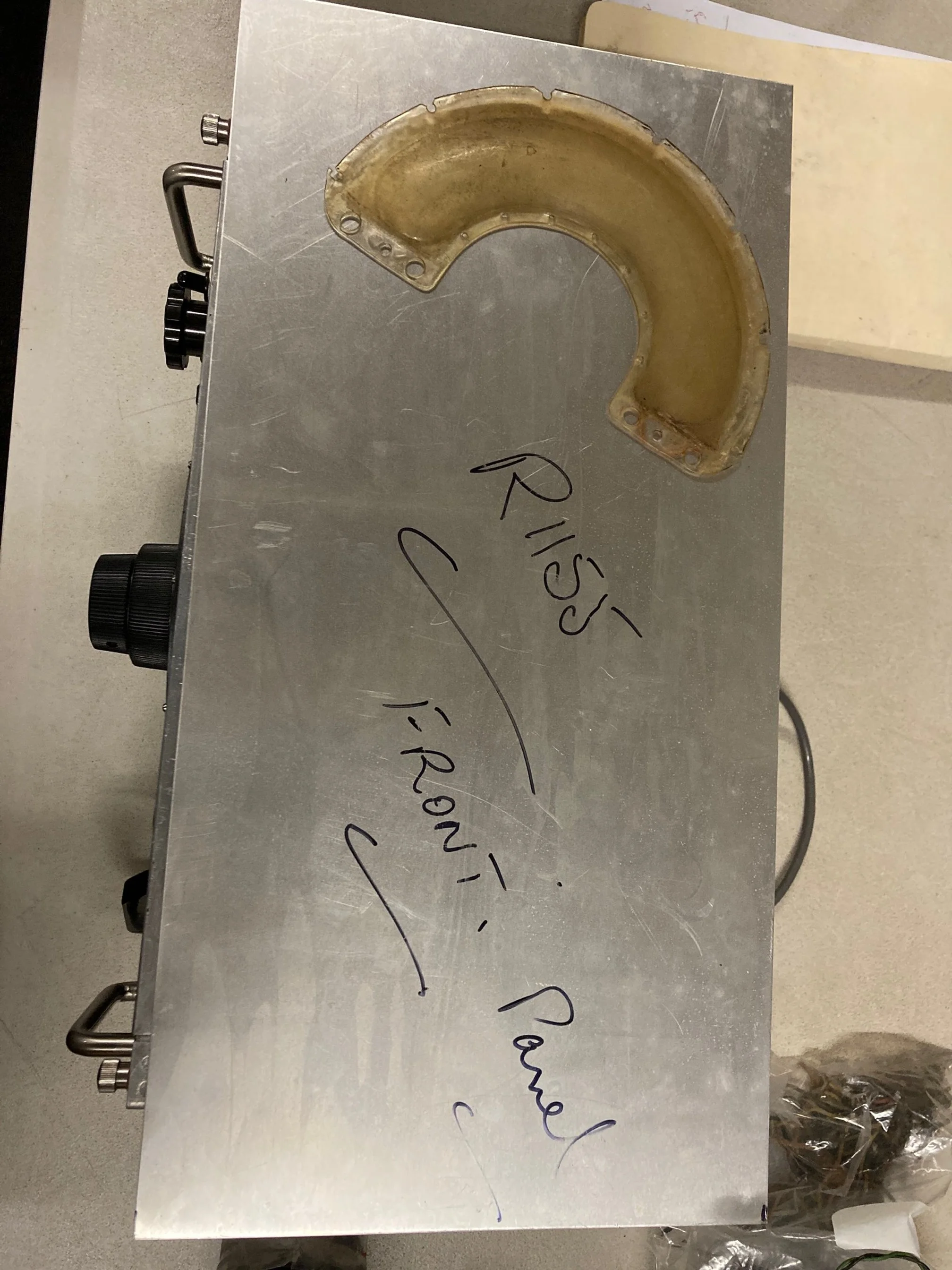

The front panels were a different story, there were too many modifications in the form of holes and cut-outs that it was just not viable to repair and restore. The decision was made to make new front panels from scratch! This involved meticulously measuring every cut-out, hole for switches, control knobs, dial frequency display and even the fastening screws for each controls name plate. This information was transferred onto two new sheets of aluminium for drilling and cutting. Only a couple of control name or function plates had survived unscathed, the remainder had to be made. Making the job harder was the added problem that the lettering turned out to be a non-standard current font.

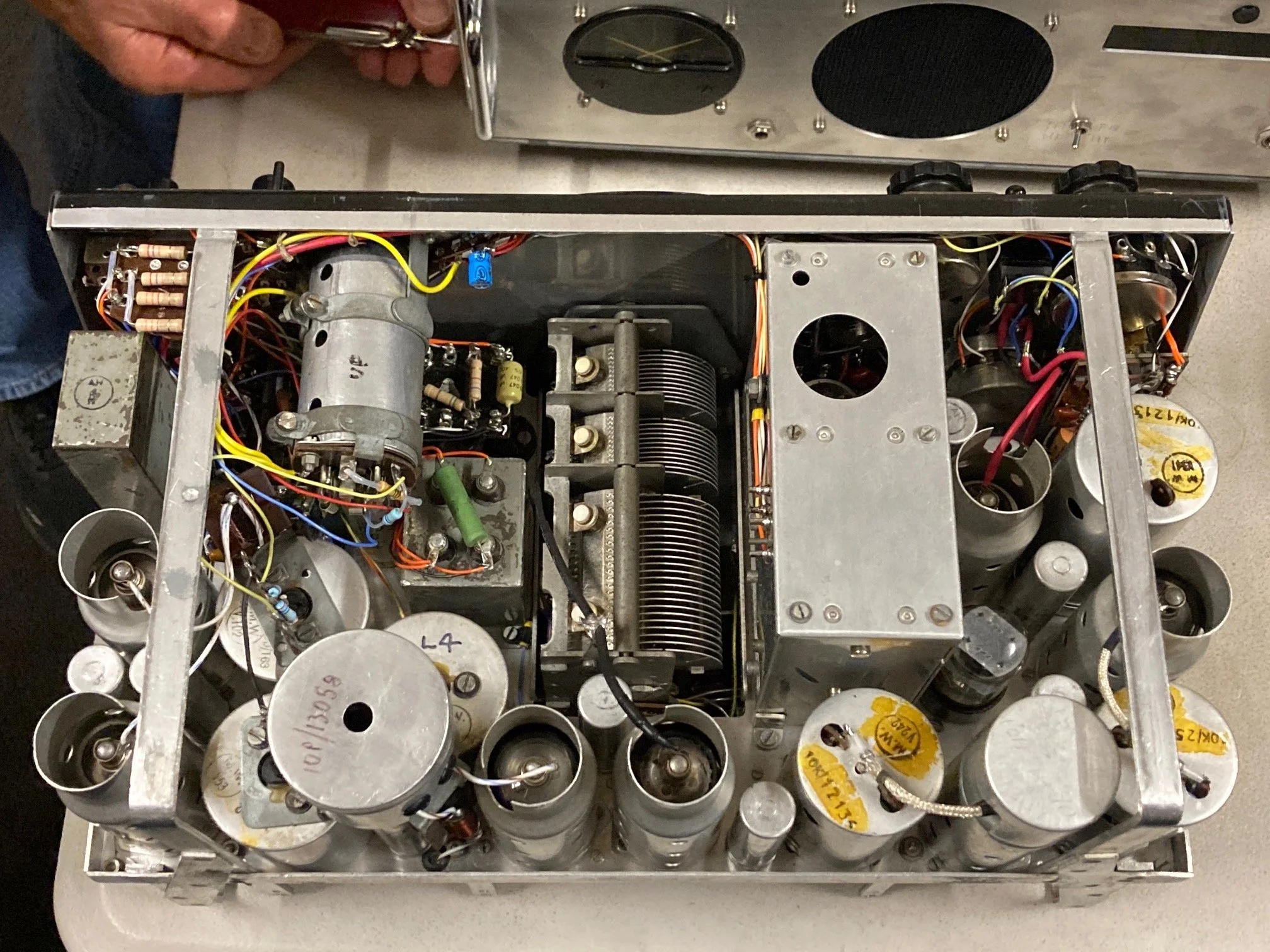

Every component and wire was removed by de-soldering every soldered joint in the receiver. Funnily enough, not one faulty or suspect original solder joint was found, which is testament to the people working on the original assembly line. Valve sockets, switches, selectors and anything of phenolic construction ended up having to be tested for integrity using an ionisation or high voltage tester. Multiple cleaning operations of the same parts became the norm and repeated until the insulation specifications were acceptable.

All capacitors were replaced because the majority of wax covered ones had melted and the others had disgorged their guts throughout the chassis. Larger chassis mounted capacitors were refitted to original position purely for visual authenticity.

All wiring was replaced with a high temperature insulated type as most of the original rubber sheathing was crumbling and the cotton and wax covered ones were also severely degraded.

Coils were rewound because the cotton insulation between windings had failed.

All the IF coils had their ferrite slugs sealed with window putty. Yes I did say window putty, but dried and rock solid, yet another problem to remove without damaging the former or ferrite slugs.

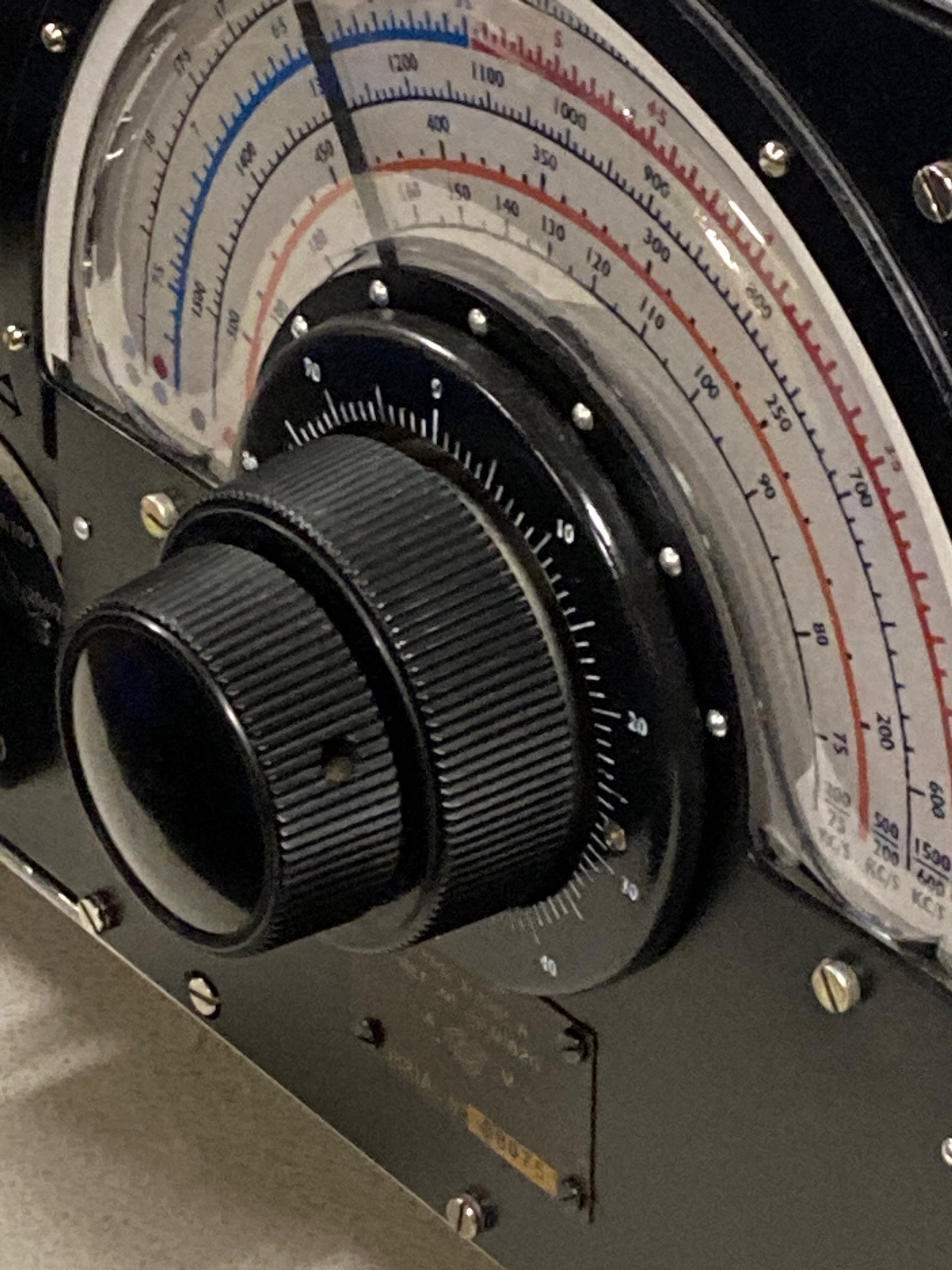

The frequency tuning dial scale has been reproduced in the original colours and looks sharp and vibrant.

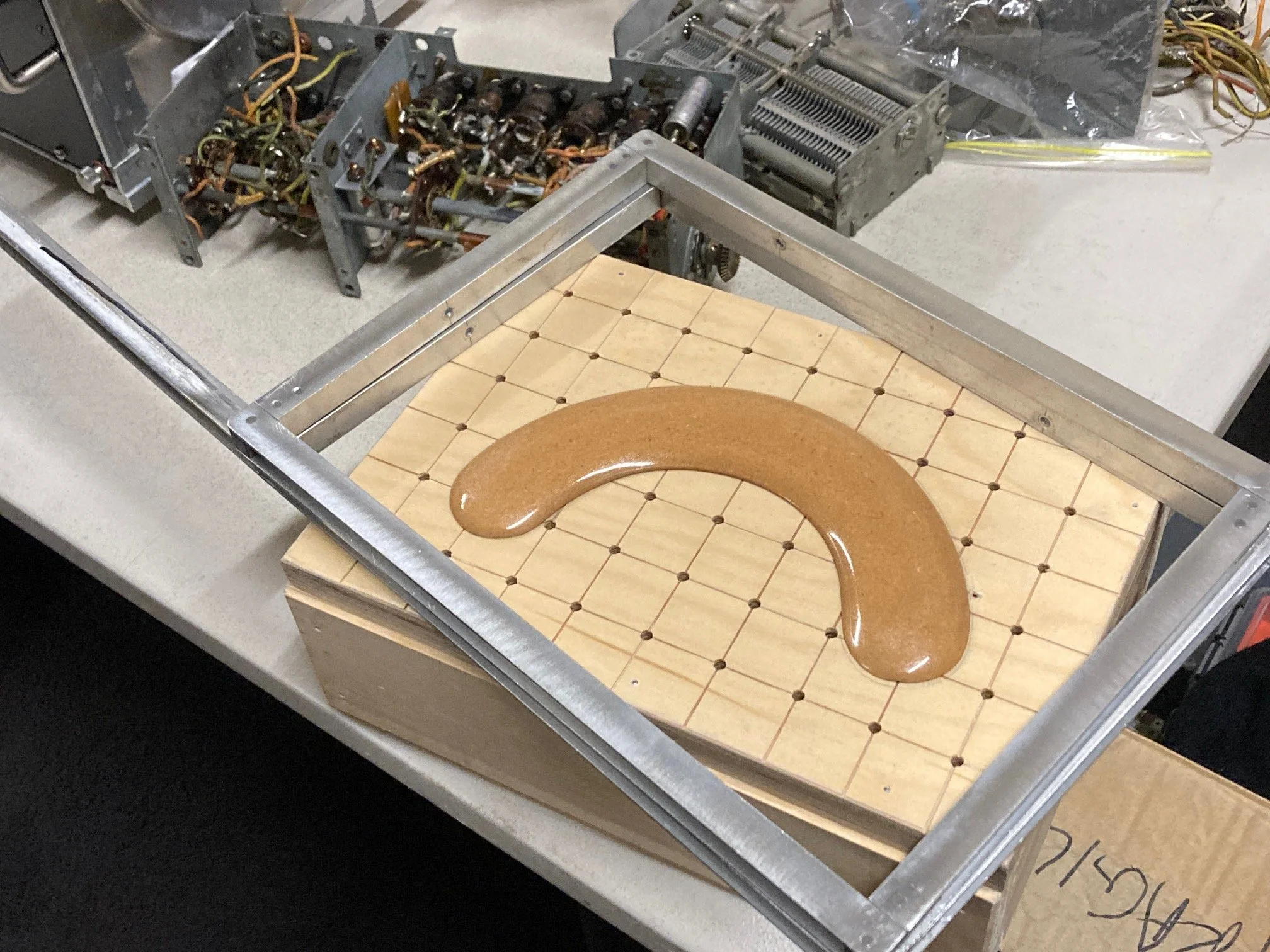

Unfortunately the original three dimensional horse shoe shaped dial windows had yellowed to the point where they were opaque and had physically shrunken, breaking all the holding bolt and rivet mountings.

Their endeavours learning the art of vacuum forming plastic is a standalone presentation in its own right. Suffice to say they recreated the profile and succeeded in forming a new transparent dial window.

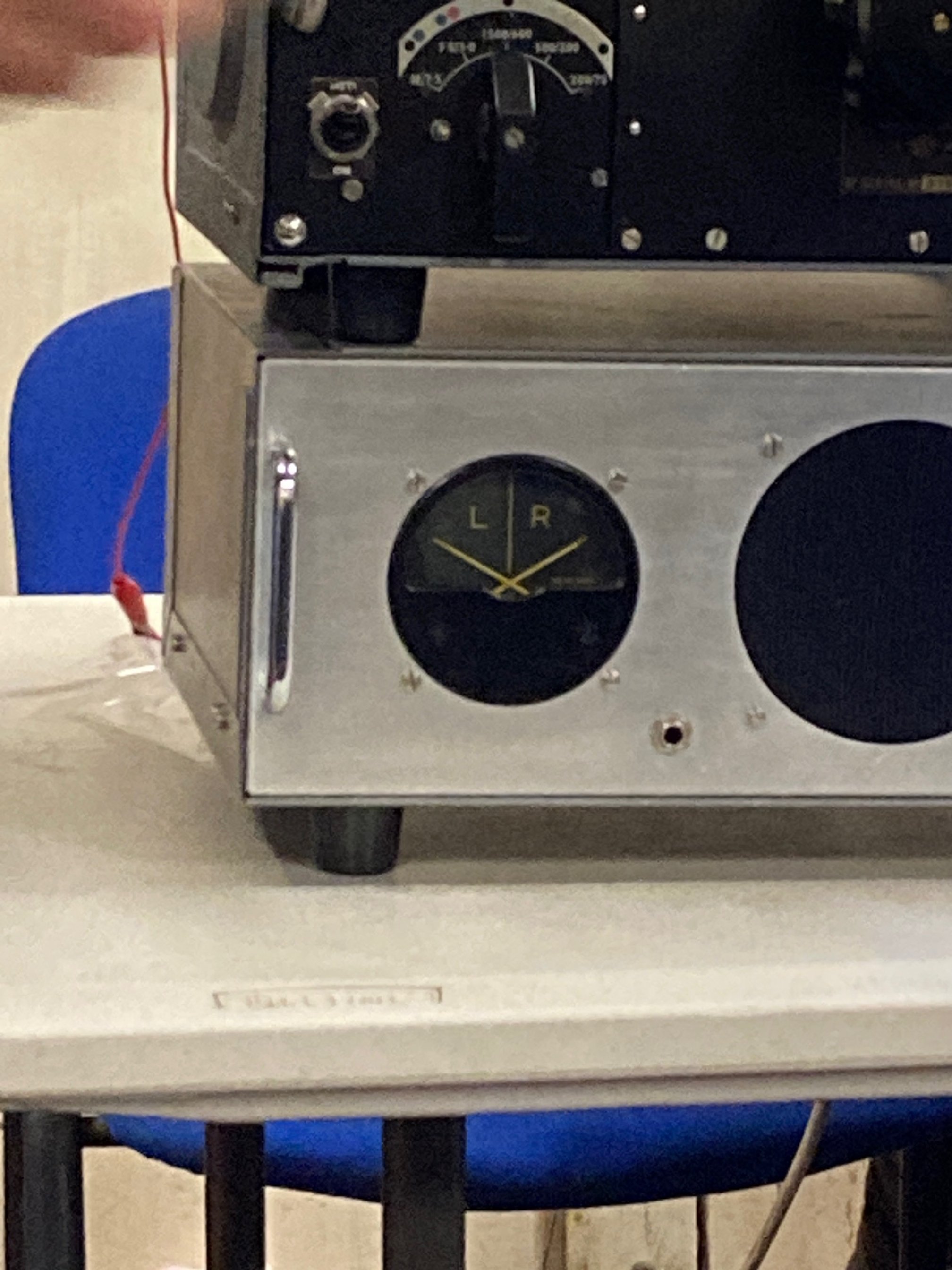

Eric had also constructed an external power supply unit using the same fabrication method and footprint as the Marconi receiver. Once it is painted and sitting underneath the receiver it will blend in.

The new power module also contains an original “Direction Finder” meter and an auxiliary digital frequency readout added just for good measure.

This certainly has proven to be an amazing restoration journey over a number of years for Eric and Trevor. The fact that the receiver now meets or probably exceeds original specifications is a measure of their meticulous attention to detail and conscientious use of test and measurement.

As they say a picture is worth a thousand words, so just check out the pictures that will be available soon on the NTARC Web site under “Blogs” for this broadcast. NTARC Blogs

Now for a late addition - Before any more club members can ask…… “Yes!” NTARC club rooms will be opening up to watch the REAST “Chirpsounder Technology and Propagation Tool Interpretation” presentation on the 2nd July. Doors will be open by 7:00 pm, with the live REAST YouTube channel on line by 7:30 pm. See you there.

UPCOMING EVENTS

On Air Test and Technical Net session - Every Wednesday, Test-Net and CW course on 3.580 MHz from 7 pm, then a Technical Net on 3.567 MHz from 7.30 pm till 8.30 pm. Your host for the evening is Nic VK7WW.

Club Room Technical night session - The next session will be Wednesday the 25th June, from the usual time of 6.30 pm at the Club Room Archer Street, Rocherlea.

Special Club Room night session - Wednesday the 2th. July, live stream of REAST “Chirpsounder Technology and Propagation Tool Interpretation”. Doors open at 7:00 pm.

Mid-year Club get-together - Wednesday 9th July at Iron Horse Bar and Grill.

Coffee Morning - Held every Friday in the NTARC Club rooms. Time is from 10 am to noon.

Finally – If you have any items of news please email them to the Secretary at the following address news@ntarc.net all items to be received no later than 5 pm on the Friday prior to the Broadcast.

That’s all folks,

73, Stefan VK7ZSB, Secretary NTARC Inc.